销售经理: 150 3855 4363 130 1558 3380

24小时技术支持热线:15038554363

电话:0379-69766926

传真:0379-69766926

公司地址:洛阳自贸区高新区银昆科技园

生产厂址:洛新工业园

一、中频感应加热特点:

1、加热速度快、氧化脱碳少

由于中频感应加热的原理为电磁感应,其热量是由于工作自身产生,所以该加热方式升温速度快,氧化极少、加热效率高、工艺重复性好。

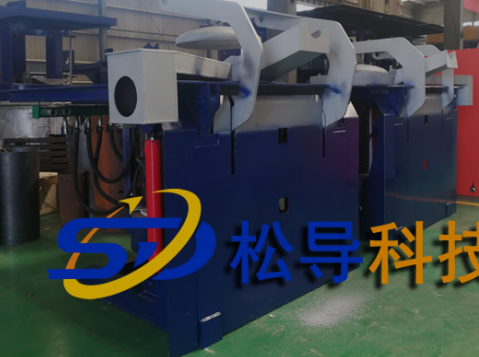

2、 自动化程度高,可实现全自动无人操作

选用自动上料和自动出料分检装置,再配上我公司自行开发的专用控制软件,可实现全自动无人操作。

3、 热均匀,温度控制精度高

加热均匀,保证加热芯表温差小。通过温度控制系统可对温度进行精确控制。

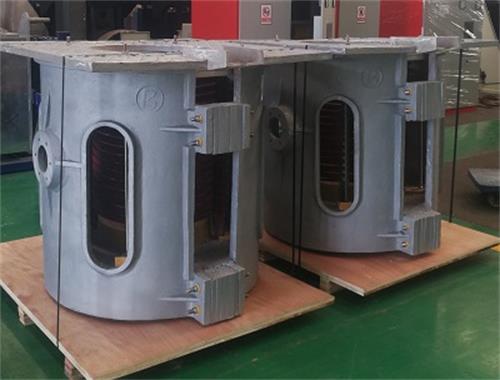

4、 感应炉体的更换简便

根据加工工件尺寸的不同,可配置不同规格的的感应炉体。可最大限度节省能源、资金。各炉体均设计有水电快换接头,使炉体更换简便、快速、方便。

5、 设备保护齐全,保证低故障率、低维修率、低损耗率

全套设备设有水温、水压、过流、过压、缺相等保护,并设有温度上、下限报警装置。使设备在故障时可靠保护,不损坏元器件。

6、 能耗低、无污染

加热效率高,与其他加热方式相比,有限的降低了能耗。设备符合环保要求、无污染。

二、技术要求:

要求对钛棒料进行感应电加热,加热温度900-1000℃,温度要比较均匀,芯表温差不超过±10℃。要求自动上料,自动进料。节拍可调。控制系统比较自动化先进。需加热钛棒表面不能受太大的摩擦,要保持表面光滑。加热钛棒的规格如下:

Φ61、68×880 Φ78、88、98、108、118、128×850

要求节拍:1分钟/根

三、全套设备组成:

1、中频电源: KGPS-500KW/0.5KHZ

2、500KW补偿电容柜

3、中频电源 KGPS-100KW/1KHZ

4、100KW补偿电容柜

5、低压开关柜:

6、加热炉: GTRF-88(加热ø61- ø88的料) GTRF-128(加热ø98- ø128的料)

7、无线圈均温炉: GTRF-88(均温ø61- ø88的料) GTRF-128(均温ø98- ø128的料) 8、提温、均温、保温炉:GTRF-88(均温ø61- ø88的料)GTRF-128(均温ø98- ø128的料)

9、自动控制操作系统

10、储料台和气动翻料机:

11、气动上料机:

12、气动推料机:

13、气动出料机:

14、两位分选机构:

15、 红外测温仪

16、水-水纯水冷却器(FSS-100)

17、连接电缆及铜排

Titanium rod medium frequency induction heating equipment

First, the medium frequency induction heating features:

1, fast heating, less oxidative decarburization

Since the principle of the intermediate frequency induction heating is electromagnetic induction, the heat is generated by the work itself, so the heating mode has a fast heating rate, little oxidation, high heating efficiency, and good process repeatability.

2, High degree of automation for fully automated unmanned operation

The automatic unloading and automatic discharge sorting device is selected, and the special control software developed by our company can be used to realize automatic unmanned operation.

3, Uniform heat and high temperature control accuracy

The heating is even, and the temperature difference of the heating core is small. Temperature control is precisely controlled by a temperature control system.

4, Easy replacement of induction furnace

Depending on the size of the machined workpiece, different sizes of induction furnaces can be configured. It can save energy and capital to the utmost. Each furnace body is designed with a water and electricity quick-change joint, which makes the furnace body replacement simple, fast and convenient.

5, Complete equipment protection, low failure rate, low maintenance rate, low loss rate

The complete set of equipment is equipped with water temperature, water pressure, over-current, over-pressure and lack of protection, and has upper and lower temperature alarm devices. The device is reliably protected in the event of a fault without damaging the components.

6, Low energy consumption and no pollution

High heating efficiency and limited energy consumption compared to other heating methods. The equipment meets environmental protection requirements and is non-polluting.

Second, technical requirements:

It is required to inductively heat the titanium bar material, the heating temperature is 900-1000 ° C, the temperature is relatively uniform, and the temperature difference of the core watch does not exceed ± 10 ° C.Automatic feeding is required, and automatic feeding is required. The beat is adjustable. The control system is more advanced and advanced. The surface of the titanium rod to be heated should not be subjected to too much friction, and the surface should be kept smooth. The specifications for heating the titanium rod are as follows:

Φ61, 68 × 880 Φ78, 88, 98, 108, 118, 128 × 850

Request beat: 1 minute / root

Third, the complete set of equipment:

1. Medium frequency power supply: KGPS-500KW/0.5KHZ

2, 500KW compensation capacitor cabinet

3. Medium frequency power supply KGPS-100KW/1KHZ

4, 100KW compensation capacitor cabinet

5, low voltage switch cabinet:

6. Heating furnace: GTRF-88 (heating ø61- ø88 material) GTRF-128 (heating ø98- ø128 material)

7, no coil equalizing furnace: GTRF-88 (average temperature ø61- ø88 material) GTRF-128 (average temperature ø98- ø128 material) 8, warming, temperature, holding furnace: GTRF-88 (average temperature ø61 - ø88 material) GTRF-128 (average temperature ø98- ø128 material)

9, automatic control of the operating system

10. Storage platform and pneumatic turning machine:

11, pneumatic feeder:

12, pneumatic pusher:

13, pneumatic discharge machine:

14. Two sorting institutions:

15, infrared thermometer

16. Water-water pure water cooler (FSS-100)

17, connecting cable and copper row

电 话:0379—69766926 手 机:13015583380